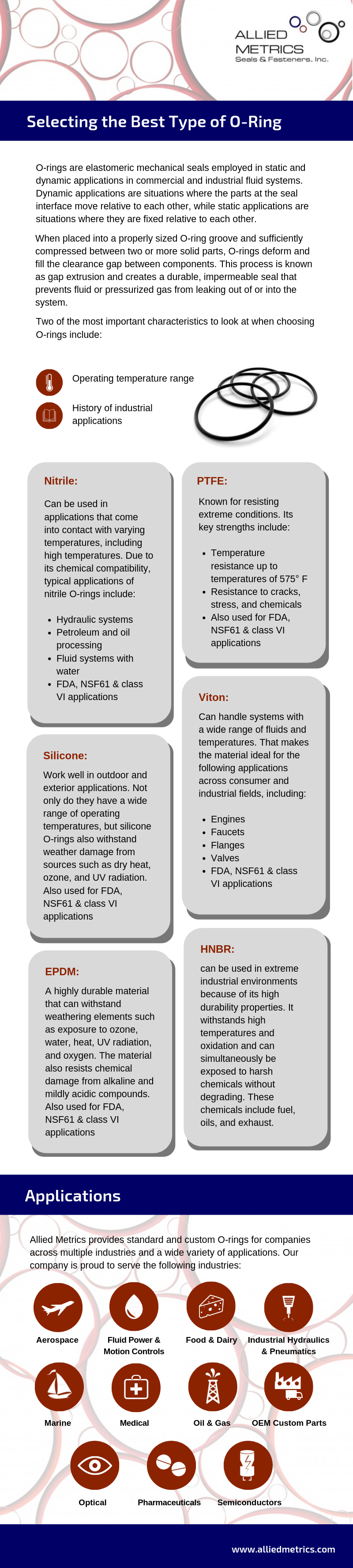

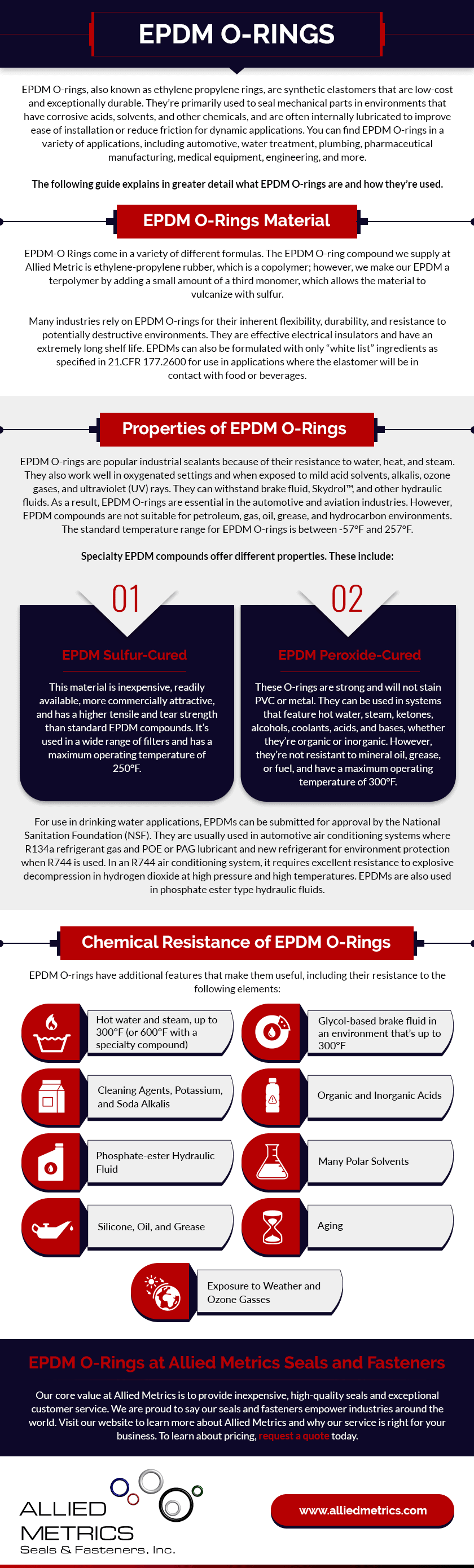

About epdm ethylene propylene diene monomer epdm has a great acceptance in the sealing world because of its excellent resistance to heat water and steam alkali mild acidic and oxygenated solvents ozone and sunlight uv.

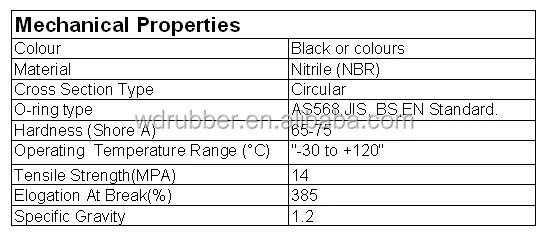

Epdm o ring material properties.

Global o ring and seal llc is a master distributor of o rings backup rings x rings cord stock and related seals servicing industrial distributors worldwide.

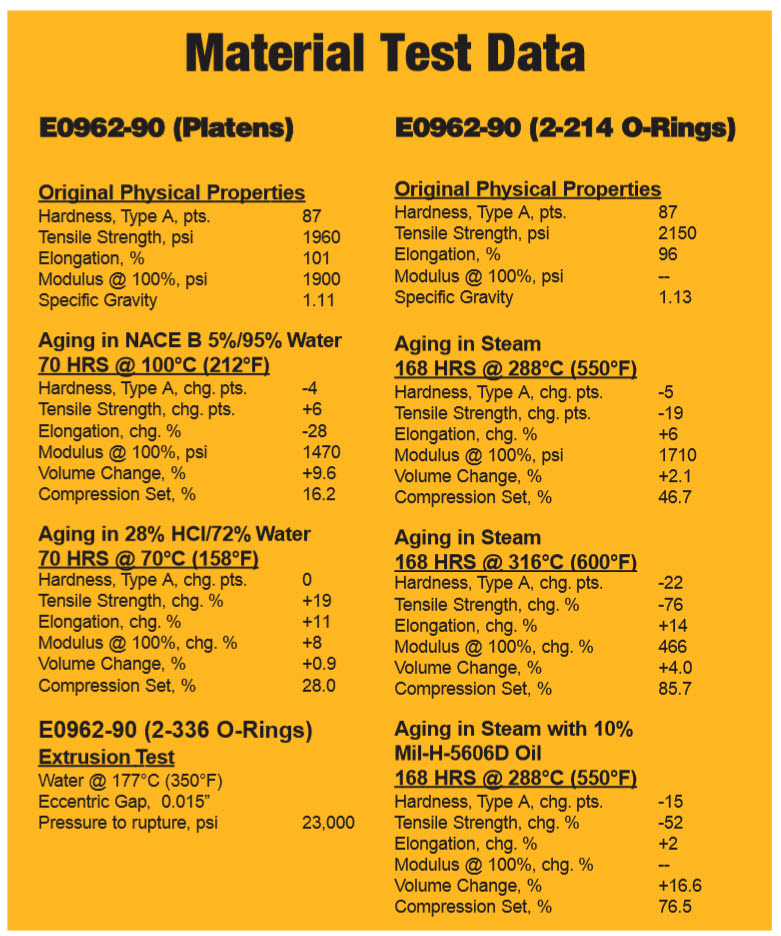

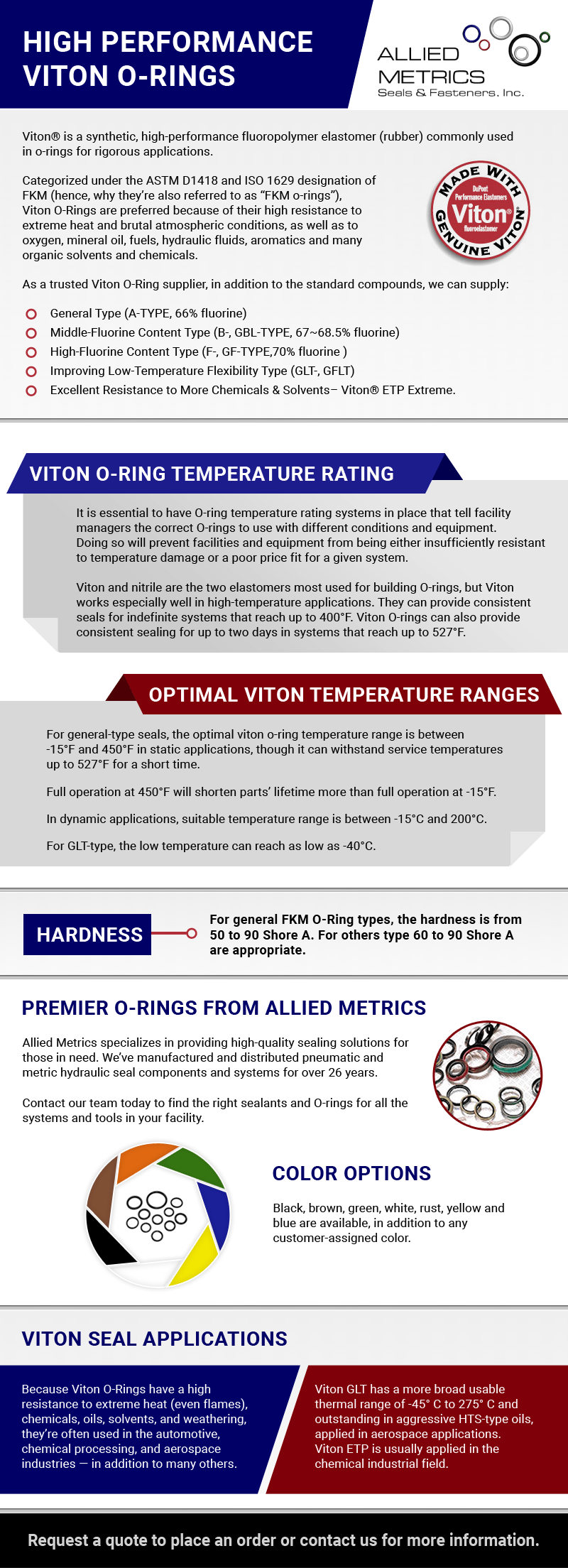

Has an operating temperature range of 60 to 300 f 51 to 150 c and a hardness range of 40 90 durometer.

These compounds also withstand the effect of brake fluids and skydrol and other phosphate ester based hydraulic fluids.

General properties compatibility more epdm ethylene propylene diene monomer m class rubber is a type of synthetic rubber that is popular for a broad spectrum of applications.

Of all the rubbers epdm is the most water resistant which is why it s so popular for outdoor applications and is often used as a roofing material.

Made of epdm they resist water steam ethanol and ethylene glycol.

Its durability is one of the properties which sets epdm apart.

The epdm lip seal is a good all round rubber quality suitable for a wide range of applications.

Water and steam resistant epdmo rings for high polishmetal sanitary tube fittings.

Epdm stands up to harsh weather conditions such as sleet and snow.

We stock all major compounds including buna nitrile viton fkm epdm silicone teflon aflas etc.

The epdm properties that are listed below are for our most popular epdm 70 durometer 70a rubber material.

Some of the most common uses of epdm include in solar panel heat collectors as tubing for electrical insulation and of course in o rings.

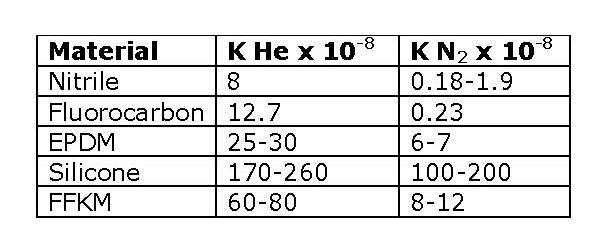

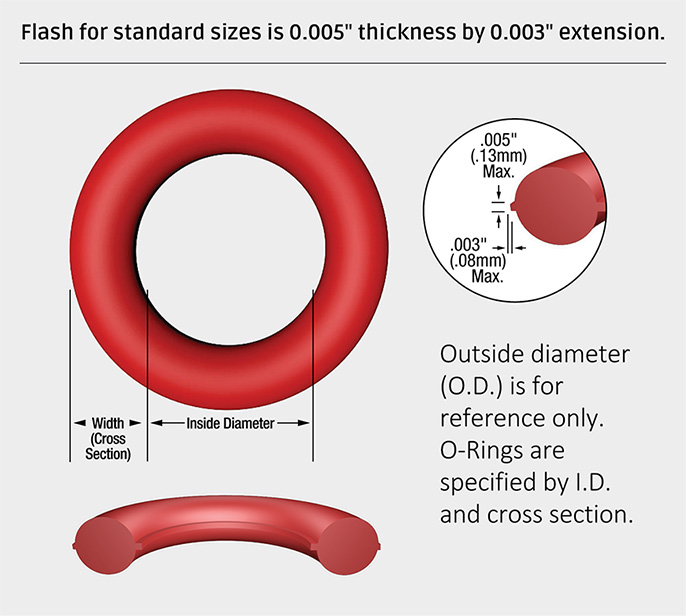

O ring material family chemical compatibility temperature resistance and other properties all factor in to o ring material selection for an application.

This popular o ring material family comparison shows basic rubber material family properties and performance plastic properties.

Epdm this sealing ring is black and made of ethylene propene rubber.

The pros of epdm epdm has a stable saturated polymer backbone structure which gives the material its advantages.

This is blücher s standard sealing ring and it is suitable for all rainwater and waste water installations where there is no oil or no petrol residues in the waste water.

Finding the correct material especially if you are using it for an o ring seal is important as the rubber can degrade quickly if the material is not compatible with your environment.

A synthetic rubber providing excellent chemical resistance and heat resistance.

Both abrasion resistance and tear resistance are good to excellent making it suitable for dynamic applications.

O ring material quick reference guide rubber sealing materials.